THE PROCESS

With Regreen Panamá, the process begins by placing waste material on to the initial conveyor.

WASTE

PROCESS

POWER

TOTAL WASTE SYSTEM (TWS)

The total waste system (TWS) is a patented process using specialized technology to turn any solid waste material into a marketable product. Recovery facilities normally have to remove recyclable materials from the sorting line and the remaining waste is then landfilled. However, with the introduction of Regreen Panamá, that is no longer the case.

UTILIZING REGREEN PANAMÁ SYSTEMS

Technologies and Processes

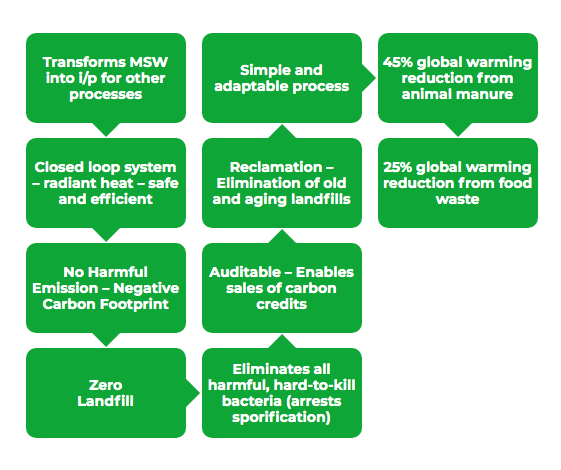

Technology Benefits

Trash is converted to pellets/fluff, then sold on open market to major users. Another additional option is to add back-end modules to the Regreen Panamá, further monetizing the pellets by converting them into other usable/marketable products like electricity, animal feed, other gases (H or N), rubber filler, etc.

THE PROCESS

- Equipped with hydraulic pusher moving waste towards the shredding drum.

- The system uses patented blade cooling system.

- It can shred from thin to thick plastic films to toughest palm fronds.

- The waste is processed into uniform sizes of 50 millimeters or less.

- Uniform size and smaller particles are vital to the process since it helps the system to quickly kill bacteria, germs, and eliminate odors.

- During the initial unloading stage (prior to shredder), the odor is initially controlled by a built in mist/spray system.

- The Regreen Panama Radiant Heat Moisture Extractor will process the shredded waste to reduce the bacteria and odor causing pathogens.

- It is designed to lower the moisture content to less than 10%.

- It utilizes INDIRECT dry steam or oil for energy.

- After exiting the Radian Heat Moisture Extractor, the waste will transfer to the Press.

- It is designed to further remove the moisture content by 40%.

- The liquid extracted from the process is gathered and transferred to a special filtration system via a pump.

- The dirty water from the press is ran through sand filters first.

- The waste water is further filtered through activated carbon filters.

- The process adds chemicals to the water in order to reclaim it and in effect brings it back up to irrigation standards.

- The reclaimed water can then be used for cleaning, farming, or any other on/off site uses.

- While the extracted liquid is going through the reclaim process, the solids are transferred to the Radiant Heat Processor via the conveyor belt.

- At this stage, solids are further stabilized and the leftover moisture gets extracted and turned into a vapor, leaving the solids with the desired moisture level (as low as 4%).

- It also disintegrates many of the toxins that are found in the MSW.

- It utilizes INDIRECT dry steam or oil for energy.

- A grinder is then used to prepare the material for pelletizing or briquettes.

- The pellets can be made to any specification.

- This system uses Regreen Panama pellet-chilling unit to create a long lasting and high value commodity for energy applications.

- If only organic waste is used, the end product can also be used as fertilizer and/or animal feed.

- Regreen Panama pellets burn cleaner than any other source of fuel, and have a high BTU value.

- Our pellets do not produce smoke while burning and burns longer due to compact of the pellets.

- Smoke from the pellets if any, would be the Syngass

- Some applications will not require pellets, so material straight from the dryer (aka “fluff”) or ground into a powder form are also options.

- Pellets, fluff, and powder are highly marketable for energy production, even when not in pellet form.

In summary

Regreen Panamá TWS processed material (garbage or organic waste) performs better than any other processed material in gasifiers or applications that use coal for energy production. The Regreen Panamá process eliminates odor, greatly reduces harmful bacteria, and viruses from garbage and/or organic waste. Our system also effectively homogenizes the processed material. These unique actions and benefits, along with the lowest moisture content produced by any system in the world, creates end products (pellets/fluff/powder) that are significantly lower in emissions and avoid clinkering issues in all energy production applications.

Let's Bring Less Waste and More Life to Your City.

Let us know your necessities and we provide the system and addons for your specific area.